How many times have you looked at

that dead servo on the corner of your bench and wished that you

did not have to buy another?

I had 6 dead servo's that I

picked up cheap through E-Bay, all were mechanically sound, it

appeared that the previous owner had fried them with too much

supply voltage. They were a mixture of Futaba, Hitec and Acoms

servo's. After stripping them all to check that they were ok

mechanically, I looked through my other servo's for one the had

the simplest circuit to replicate, this ended up being the GWS

Premium Servo.

The main reason for this was that

the components were easy to get in Australia. I tested the GWS

Circuit with all the servo's first to check that it worked.

Construction

To build this circuit you will

need to be able to make Printed Circuit boards, if you can't then

you will need to learn how to and set yourself up with the right

equipment.

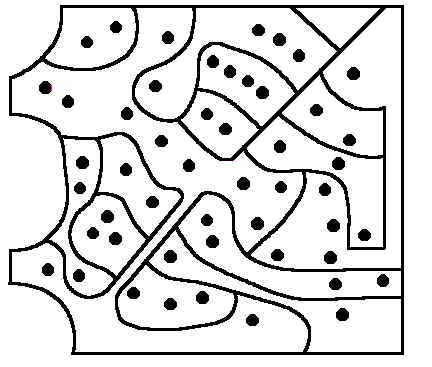

The circuit board was a cut down

replica of the GWS board. The copper side layout is shown below;

Note; This is

shown a lot larger than it needs to be the proper size for this is

17 x 16mm.

Firstly start by making the PCB

as per the layout above. Once you have made the PCB. You can start

installing components into the PCB and soldering them on. The

components you will need are;

Parts List - Servo Controller

Item Description

C1 0.01uf Ceramic Cap

C2 0.01uf Ceramic Cap

C3 0.01uf Ceramic Cap

C4 22uf Tantalum Cap

C5 22uf Tantalum Cap

C6 0.1uf Tantalum Cap

C7 .47uf Tantalum Cap

R1 22k 1/4 Watt

R2 820 ohm 1/4 Watt

R3 470 ohm 1/4 Watt

R4 39k 1/4 Watt

R5 330k 1/4 Watt

IC1 M51660L

Mitsubishi (Oatley Electronics has these)

IC2 BC640 PnP Transistor (The original was a HE5550)

IC3 BC640 PnP Transistor (The original was a HE5550)

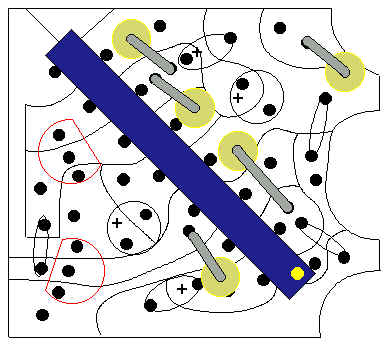

The following two diagrams show

the layout for the components into the PCB (this is a top view of

the PCB);

The first diagram shows the

polarity of the components;

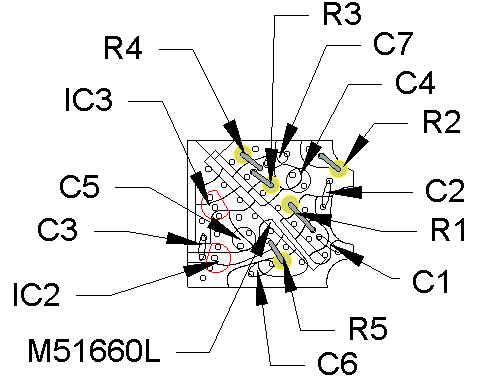

The next identifies each of the

components and there location;

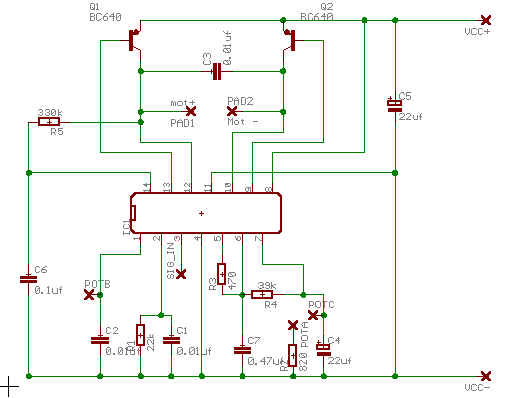

The schematic for the circuit is

shown below;

Hooking it up

Once you have got the PCB and its

components solder in and you have double checked that you do not

have anything in the wrong way and that there are no tracks joined

as a result of soldering in the components. You can now move on to

the hook up to the servo.

All of the servo's I have fixed

have had a 5k Pot to sense the position of the output shaft of the

Servo. The circuit is designed around this and you will need to

check that the Pot in your servo is 5k. To do this remove the pot

from the servo housing and them place a suitable resistance meter

across the two outer most terminals of the pot.

Check the reading, if it does not

read around 5k, then you may not be able to use this circuit. I

have never had to worry about this, however you can still try it,

if it works let me know.

There are seven hook up points;

The only thing that will happen

if you get them wrong is that the servo will not respond correctly

to your commands and when you power it up it will wind all the way

to one side and stay there. If this happens then reverse the

connections to Pot A and C and all should be fine. Pot B is always

the middle.

To hook up the motor + and -, you

simply need to look at the back of the servo motor and there will

be a red dot on the positive side. Hook this to the Mot + and the

other to the Mot -. Some servo's have and additional capacitor

across the terminals of the servo motor, you can remove this if

you want, the circuit has a capacitor on the PCB to do the same

job.

Hook up the SIG, Rec + and Rec -

wires as shown.

Now check that you have not

soldered over the tracks and that all components are in the

correct spot. Also use a Multi-Meter set at a low Ohmage and test

on the backside on the PCB to make sure nothing is shorted out.

You can use the schematic as a guide to which parts of the circuit

should be connected to which other parts.

If you get a connection between

to tracks, double check everything.

After you are sure that is is ok,

then;

- Remove all servo drive gears

from the servo, making a note of how they came off and where

they fit (take a photo if you have a digital camera). This

should only leave the drive gear from the Servo Motor and the

pot shaft left in the servo.

- Place the output drive gear on

the Pot shaft as it would be normally.

- Take a spare battery pack and

through a connect it directly to the servo. You will need and

adapter to do this, I just use short bits of left over wire

from the resistors to make the bridge. Please make sure you

have the polarity right i.e.; Black servo wire to the negative

side of the battery and the Positive Servo wire to the

positive side of the battery.

- If all is correct the servo

should spin a little and then stop. If this does not happen

double check every thing again and if it still does not

happen, check the signal wire from the servo to make sure

there is no voltage on it. If there is you have a problem and

you need to check again. If not then you should be safe to

plug it into the receiver, as some servo's don't spin when you

hook them to the battery.

- If all is ok then unplug the

battery and plug the servo into the receiver and then plug the

battery in. If nothing happens except a little spin of the

motor then all is fine so far. If something else happens, go

back and check again.

- Now turn on your Transmitter,

the servo should start to spin immediately, if it does not

turn the output gear all the way in one direction. If the

servo starts to spin, all is well, if not then unplug every

thing and check again.

- You will find that if you turn

the output gear from right to left, there should be a spot in

about the middle that the servo slows down and it should stop.

If it does this you have done a great job as this is what

should happen. If it does not then you need to go back and

check again.

- If all is ok then you can

re-assemble the servo putting all gears back into place and

placing the circuit board into the servo case. Make sure that

the components on the PCB do not cause the connections to the

pot to short out etc.

- Double check that all is well

and then screw the covers back on the servo. It should now

look like it is a real servo.

- After you get the this stage,

then replug the servo onto the battery and check that it still

move a little.

- If it does then plug it into

the Receiver and attach the power to the receiver, it should

move, if it does good, if it does not then check again to make

sure every thing is ok.

- Turn on the transmitter.

- If the servo moves a little

and stops, this is good. If it moves all the way around to one

side and stops, this is bad. If it does this then the wires on

the pot are on the wrong way, you will need to reverse Pot A

and Pot C.

- If all is ok then move the

stick for the channel that the servo is plugged into. it

should move and operate normally. if it does not then you have

to go back and check.

I have repaired 6 servo's this

way and they all work and are still working (over 6 months). I

would suggest that you take several precautions when you first use

your repaired servo.

I hope this is as of as much

benefit to you as it was to me, if you have comments, suggestions

or anything else to say about this, please contact me.

Terms of Usage

This information

can be used only for non-commercial purposes, it can only be used

for commercial purposes with the written approval of the Author.

It can be freely distributed as long as reference is made to the

author wherever it is displayed or used. The Author takes not

responsibility for any inaccuracies in this document and also for

any loss, damage or injury the information presented here may

cause. If you have a all correction, contribution or suggestion

that you wish to share with the Author, please send an email to craig@willingtons.com

replies will not be guaranteed.